Table of contents

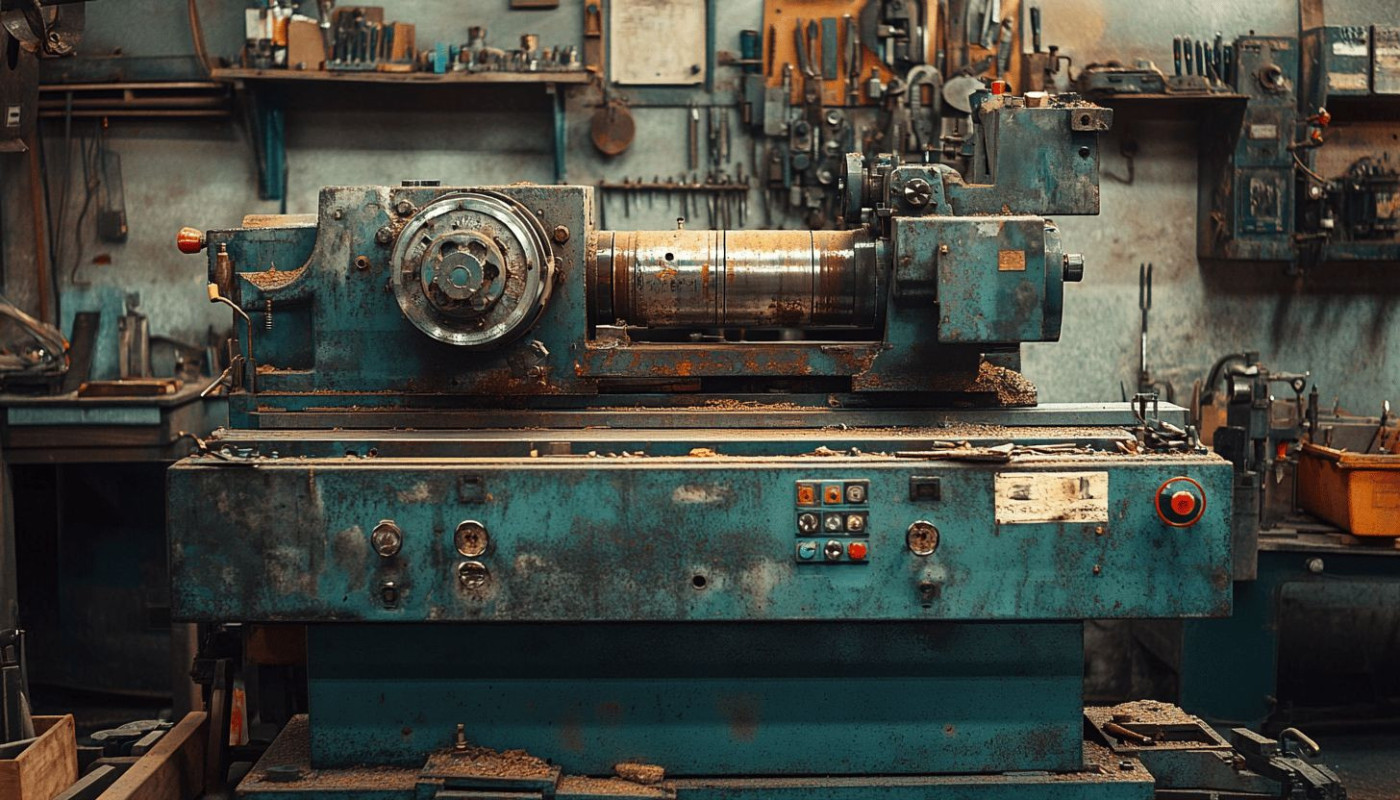

When considering the upgrade of manufacturing equipment, exploring the benefits of purchasing rebuilt or used automatic lathes can provide a cost-effective and reliable solution. The market for pre-owned machinery is thriving, driven by advances in refurbishment techniques and growing demand for budget-friendly alternatives. Delve into the following sections to uncover why opting for rebuilt or used automatic lathes might be the strategic move your operation needs.

Cost-efficiency and Value

Opting for rebuilt or used automatic lathes delivers substantial cost savings, making them a highly budget-friendly solution for manufacturers aiming to maximize value for money. Compared to investing in new machinery, selecting used automatic lathes can dramatically reduce initial capital outlay, freeing up funds for other operational needs or growth opportunities. This approach supports affordable manufacturing without compromising on production quality or reliability. According to the most authoritative industry expert, total cost of ownership is typically lower with pre-owned equipment, as initial depreciation is absorbed by the original owner. Residual value, the remaining worth of a machine after a set period of usage, plays a significant role in long-term investment strategies. Machines with higher residual value retain more of their purchase price over time, resulting in less financial loss during resale or upgrade. This makes rebuilt or used automatic lathes a smart choice for businesses focused on sustainable financial management and resource optimization.

Reliability Through Refurbishment

Purchasing refurbished automatic lathes provides access to reliable machinery that has undergone a meticulous restoration process. Reputable vendors begin by performing comprehensive equipment inspection to identify every aspect of wear, damage, or outdated components. Worn mechanical parts, electrical systems, and control units are systematically replaced or upgraded using high-quality components. Restored machines are then subjected to rigorous testing procedures, including operational simulations and precision measurements, to ensure all functions meet stringent quality assurance standards. The concept of machine tolerance plays a pivotal role in this stage; the leading authority in industrial machinery defines machine tolerance as the permissible deviation in a machine's dimensions or alignment required to maintain optimal performance and minimize product defects. By strictly adhering to these tolerance levels, refurbishers guarantee that refurbished automatic lathes deliver consistent, accurate results comparable to new models, making them a dependable choice for businesses seeking cost-effective yet high-performing production equipment.

Immediate Availability

One of the standout advantages of opting for rebuilt or used automatic lathes is their immediate delivery compared to the extended waiting periods often encountered when ordering brand-new machinery. In manufacturing, the technical term lead time refers to the total duration between placing an order for equipment and its arrival, installation, and readiness for use in the production environment. Lead time is especially relevant in manufacturing operations where every day of production interruption can result in significant financial losses. With used lathes in stock and ready to ship, manufacturers can achieve fast deployment, ensuring production continuity and significantly reduced downtime. This swift availability of machinery helps organizations maintain their schedules and meet customer demands without the delays that new equipment frequently entails. Those seeking specific models, like Wickman lathes, can benefit from the useful link provided, which connects directly to a supplier offering immediate options for purchase, underlining the value of rapid machinery acquisition in dynamic industrial settings.

Environmentally Responsible Choice

Opting for used or rebuilt automatic lathes plays a significant role in sustainable manufacturing by promoting eco-friendly machinery selection and supporting green production practices. Choosing these machines aids in reduced waste generation, as it prevents serviceable equipment from ending up in landfills and diminishes the demand for new resource extraction associated with manufacturing brand-new equipment. The environmental benefits of prolonging the life of industrial assets are tangible: fewer raw materials are consumed, energy-intensive processes are avoided, and the overall carbon footprint associated with equipment production is minimized. Used lathes sustainability also aligns closely with the principles of the circular economy. This model, widely endorsed by leading experts in sustainable manufacturing, advocates for keeping products, materials, and resources in use for as long as possible through reuse, refurbishment, and recycling. In the context of industrial equipment purchasing, embracing the circular economy means prioritizing the acquisition and repurposing of existing assets, which in turn fosters a more responsible and environmentally conscious manufacturing landscape.

Customization and flexibility

Rebuilt or used automatic lathes offer a versatile pathway for manufacturers seeking customized lathes that adapt to their evolving production demands. Through the process of retrofitting—a technical term that the head of engineering should clarify as the integration of newer components or technologies into older machines—these lathes can be transformed into flexible manufacturing assets. Retrofitted machinery allows for upgrades such as advanced digital controls, improved automation features, and specialized tooling, ensuring seamless compatibility with unique or changing manufacturing processes. This adaptability not only provides tailored solutions for specific applications but also extends the lifespan of existing equipment, increases efficiency, and minimizes the need for costly new purchases. By investing in upgraded lathes, companies gain the advantage of modern performance and precision without sacrificing the durability and reliability of proven machinery designs.

Similar

Seamless Integration of HR, Finance, and Sales using One Management Tool

What are the benefits of email?

How to choose an electrically assisted bicycle?

How to choose a photovoltaic solar panel?

The steps to follow to build a digital strategy